View Larger Image

There is also a growing need for ball valves as the world seeks more alternative sources of energy. Apart from China, ball valves can also be found in India. There is no denying the importance of such valves in any industrial piping systems. But, much is to be learned about ball valves, and you should know it before you use it. This article will help you understand ball valves more so you’d learn whether these are suitable for your applications.

What You Should Know about Ball Valves

One of the most commonly used industrial valves, ball valves are often employed in tight shut-off applications. The ball valve got its name from the hollowed-out sphere component that allows media passage when it opens or blocks it when closed. These are members of the quarter-turn family of industrial valves.

The ball valve is often used in many industries so it’s not surprising to find that its demand is high. Nowadays, you can find high quality made in China ball valves or ball valves manufactured in India.

Common Ball Valve Features

Many ball valve types share the same features as mentioned below:

# Swing check – this prevents backflow of media

# Valve stops – this allows only a 90-degree turn

# Anti-static – this prevents static electricity buildup that can cause sparks

# Fire-safe – a secondary metal seat is built to act as supplementary seats in high-temperature applications.

Advantages and Disadvantages of the Ball Valve

Ball valves are great to use when the system needs a quick opening and closing. These are also advantageous in applications where it needs a tight seal without having to consider high internal pressure.

However, ball valves have limited throttling capacities. In fact, these are not recommended for regulating media flow. Ball valves have partially exposed seats, which can erode quickly when slurries are used. These are also hard to open quickly and manually when pressure is high.

Common Ball Valve Materials

Ball valves come in different materials. Depending on the nature of the application, ball valves are often forged or cast using iron, stainless steel, and other steel alloys. Ball valve seats can be made of an elastomeric material such as PTFE or metal, often stainless steel.

Ball Valve Parts

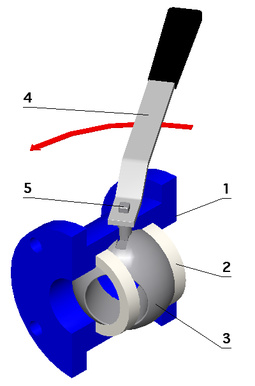

Although there are several variants of the ball valve, there are five common components present in all ball valves as seen in the diagram below:

# Body

The body holds all the components together

# Seat

The seat seals the valve during shut-off

# Ball

The ball allows or blocks the passage of media.

# Actuator

The actuator or lever moves the ball so the latter can open or close.

# Stem

The stem connects the level to the ball.

Ball Valve Ports

Typically, ball valves have two ports. But with the advent of new services, ball valves can have up to four ports. These are often branded as two-way, three-way or four-way ball valves. A three-way valve can have an L-configuration or a T-configuration.

Ball Valve Working Mechanism

The ball disc is opened or closed by turning the actuator a quarter turn or 90-degrees. When the lever is parallel to the flow of media, the valve allows the latter to pass through. When the lever becomes perpendicular to the flow of media, the valve blocks the flow of the latter.

Ball Valve Classifications

Ball valves are actually classified in several ways. You might encounter valve groups based on the number of components or the type of ball valves have.

Based on Housing

You can classify ball valves depending on the number of components their bodies have. The cheapest among the three, the one-piece ball valve is made of a single block forged metal. This can’t be disassembled for cleaning or maintenance. One-piece ball valves are suitable for low-pressure applications.

On the other hand, the two-piece ball valve is made of two pieces connected by threads. This type should be completely removed from the pipeline while being cleaned or replaced. Lastly, the components of the three-piece ball valve are connected via bolts. Maintenance can be done on the valve even if it is still attached to the pipeline.

Based on Disc Design

The design of the ball is a major classification for ball valves. Aptly named because the ball is suspended at the top of the stem, the floating ball valve is the most common design of this category. As it closes, the ball moves towards the downstream opening. The pressure load helps seal the valve tightly.

On the other hand, the trunnion mounted ball design is held steady by trunnions located at the bottom of the ball. The most suitable application for the trunnion mounted ball valves are those that have large openings and high-pressure ranges, typically more than 30 bar.

Based on Pipe Diameter

Ball valves can also be categorized based on the size of the connection in relation to the diameter of the pipes. A reduced bore ball valve means that the diameter of the valve is one size smaller than that of the pipes. This causes a minimal pressure loss. One-piece ball valves often have the reduce bore type.

The full bore type types have the same diameter as that of the pipes. The advantages of this type include no pressure loss and easier cleaning. Full bore types are more expensive because of the size of the valve. Lastly, The V-shaped type has a V-shaped hole which enables precise fluid control whenever the valve is open.

Ball Valve Applications

Ball valves are often found in a wide variety of applications. Most often, you would find them in flowing systems on ships, corrosive services and fire safe protection services. These are not used in applications where contamination is an issue such as those in the food processing services. Ball valves are difficult to clean.

Summary

Ball valves are evolving together with the industries these are associated with. Being buyers, educating oneself about what ball valve is important.

Post time: Feb-25-2022